Product Center

Contact us

Service Hotline

Address: 4th and 5th Floor, South Gate, Building D, Jindao Park, Tongxin Industrial Park, No.179 Huizhi Middle Road, Lugu National High-tech Industrial Development Zone, Changsha City, Hunan Province

Crochet machine control system

Key words:

Classification:

Product Description

Product Overview

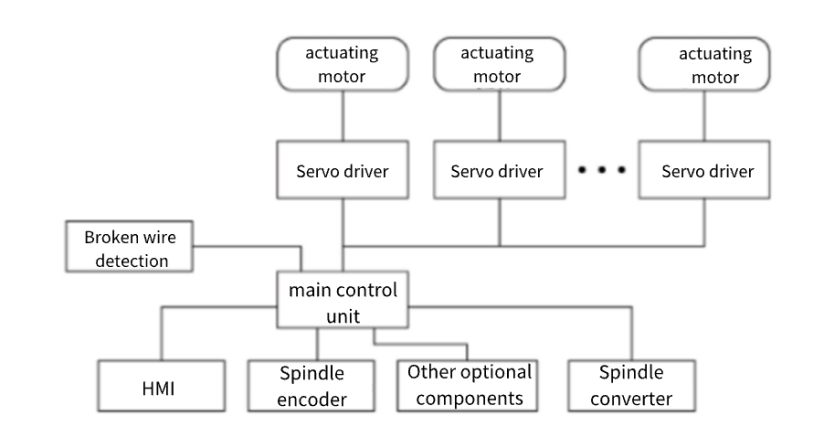

This product aims at the vacancy of domestic electronic intelligent crochet machine, replacing the flower chain chip box of the traditional mechanical crochet machine with a servo motor. Each axis is independently controlled by a single servo motor. Pattern files are stored in the control system. Theoretically, there is almost no upper limit on the number of wefts, and software can be used to make patterns on the computer.

Product characteristics

1. The control unit uses the 32-bit high-speed floating point operation CPU of ARM core, together with high-speed memory and peripheral devices, to meet the data acquisition and operation requirements of the crochet machine during high-speed operation.

2. Each comb is driven by a servo motor. With master-slave mode control mode, one master controller can expand multiple slave controllers to meet the different control requirements of 2-axis to 16 axis crochet machines.

3. The spindle frequency converter controls the main power of the machine, which can be replaced by spindle servo and other power modes according to customer needs.

4. The encoder is used to collect the spindle position, and the electronic traverse is carried out through the electronic cam algorithm.

5. The broken yarn detection device can make the machine stop in time after yarn breaking to reduce unnecessary yarn waste.

6. Special pattern making and printing software, which can be edited with excel form, is simple to operate.

7. When yarn breaks, it can stop in time and send alarm signal; It can be produced regularly and quantitatively.

Product benefits

1. High efficiency: Compared with the traditional flower chain piece, the pattern can be changed quickly, and the process can be stored and called.

2. Simplification and practicality: The comb is driven directly by a servo motor, eliminating most of the transmission structure and simplifying the installation

3. Special printing software: free pattern making through software, easy to operate and easy to use.

Control Diagram

Related Products

undefined

Leave a message