Product Center

Contact us

Service Hotline

Address: 4th and 5th Floor, South Gate, Building D, Jindao Park, Tongxin Industrial Park, No.179 Huizhi Middle Road, Lugu National High-tech Industrial Development Zone, Changsha City, Hunan Province

Rewinder control system

Key words:

Classification:

Product Description

Product overview

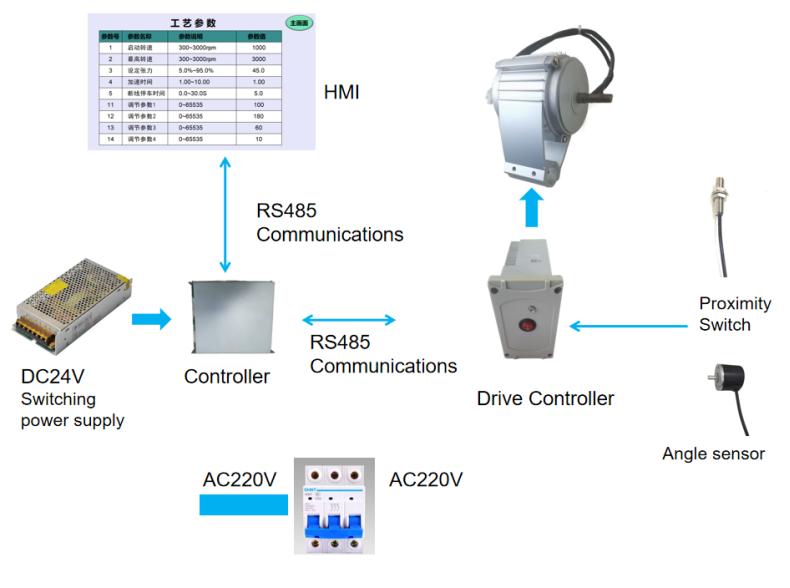

According to the winding process characteristics of the rewinding equipment of the plastic drawbench unit, we integrate many technologies in the system such as constant tension system and field bus communication. The speed of the winding motor is adjusted in real time based on the change of the tension sensor to ensure consistent and even rewinding and forming, and meet the user's needs.

Product features

1、The whole machine is equipped with human-machine interface touch screen, which allows to uniformly setting the process parameters of the whole machine

2、An operation panel is configured for each spindle, which allows to set the process parameters individually and to display the real-time speed or tension value

3、DC brushless drive is adopted for a single spindle, which saves 30% of power compared with AC inverter drive and reduces power consumption cost of end users

4、The drive mode of single spindle single control is adopted. Each spindle tension rod is equipped with an angle sensor to replace the traditional potentiometer, which ensures that the position of tension rod can be set at will and the operation is simpler

5、The sensor on the tension rod can detect the speed change of the host machine and feed it back to the single spindle controller to adjust the rewinding speed online, thus achieving synchronization with the linear velocity of the host machine

6、Automatic stop in case of yarn breakage during operation

7、Fault protection. Multiple measures are provided, such as abnormal alarm, motor stalling and hardware fault

Product advantages

1、High efficiency and energy saving: Save 65% of power compared with traditional magnetic particle motor

2、High output: Match with high-speed drawbench unit, with a rewinding speed of 550 m/min

3、Stable tension: Special angle sensor ensures even tension

4、Quality improvement: Advanced tension control algorithm ensures smooth and flat formed silk package

Control Diagram

Related Products

undefined

Leave a message