Product Center

Contact us

Service Hotline

Address: 4th and 5th Floor, South Gate, Building D, Jindao Park, Tongxin Industrial Park, No.179 Huizhi Middle Road, Lugu National High-tech Industrial Development Zone, Changsha City, Hunan Province

Digital winding and ranging control system

Key words:

Classification:

Product Description

Product overview

The system highly integrates drive control technology for high speed precision servo motors, brushless DC motors and stepping motors, and introduces high-speed transverse servo yarn guide motion control and online constant tension closed-loop control algorithm. It has been widely used in the winding and transverse ranging control of yarn winding equipment such as precision-wound winder, hank mercerizing machine, doubler winder and air covering machine, realizing highly flexible digital winding function and improved winding performance and quality. It is the best choice of yarn winding equipment.

Product features

1.Scalable factory EPR management system, which uses wireless networking to transmit data to realize networking of multiple yarn winding equipment, real-time monitoring of machine operation information, output statistics, and improvement of production efficiency of the enterprise

2.Drive mode of single spindle single control, which allows different spinning processes to be used at different spindle positions, convenient usage and maintenance

3.Electronic gear and electronic cam technology, which realizes high-speed precision winding and digital layered winding and ranging, ensures the flexibility of yarn during high-speed cross winding and forming, and improves the efficiency and quality of yarn winding

4.Winding ratio control range: 2.00~12.00

5.Full package diameter: 280 mm

6.Maximum reciprocating times of transverse ranging: 1,000 times/minute, that is, 2,000 times of commutation per minute

7.Optional online winding tension open-loop or closed-loop control. During online tension open-loop control, the winding motor speed is adjusted in real time according to the change of tension value during winding; During tension closed-loop, the constant tension throughout the winding process is realized by close cooperation of high speed overfeeding motor and high precision tension sensor. The control accuracy can reach ±5% of the set tension, which meets the winding requirements.

8.By setting the process parameters of the spindle, yarn winding of various shapes such as cylindrical, trapezoidal and tapered spindle can be realized. The parameters such as winding length, speed, winding ratio, reciprocating stroke length, differential amplitude and differential period can be freely edited on the human-machine interface of the equipment and transmitted to the controller of the specified station number through the system CAN bus communication

9.Function of automatic stroke zero finding. No external zero position sensor is required

10.A variety of spindle forming compensation curves, such as differential curve to eliminate hard edges and trapezoidal spindle side compensation curve

11.Fault protection. Multiple measures are provided, such as abnormal alarm, motor overspeed and hardware fault

Product advantages

1、Precise tension: Constant tension is ensured by closed-loop control and automatic compensation

2、Forming diversity: Electronic servo forming and edge closing without mechanical limitation

3、High output: 1,000 times/minute of ranging reciprocating

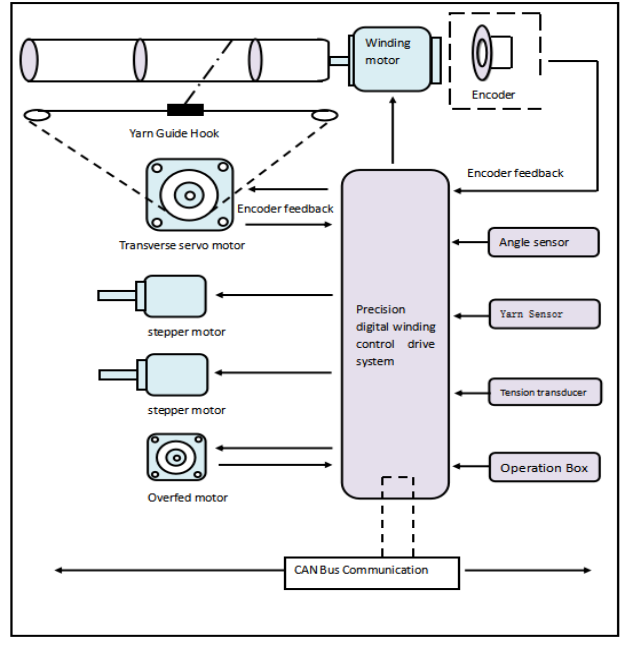

Control Diagram

Related Products

undefined

Leave a message