Product Center

Contact us

Service Hotline

Address: 4th and 5th Floor, South Gate, Building D, Jindao Park, Tongxin Industrial Park, No.179 Huizhi Middle Road, Lugu National High-tech Industrial Development Zone, Changsha City, Hunan Province

Chenille controller

Key words:

Classification:

Product Description

Product overview

The system highly integrates drive control technology for high speed brushless motors and stepping motors, and introduces motor closed-loop control algorithm. All drive parts are driven independently by motors and can be stepless speed regulation. Therefore, the system can meet various spinning and forming requirements and solve problems of large ingot formation difference, high noise and low yarn quality caused by belt drive of traditional machine with high production efficiency.

Product features

1、Intelligent man-machine interactive screen, through which twist, linear velocity, unit run time, process parameter and storage method can be set

2、Automatic stop in case of yarn breakage, which can reduce waste yarn, save cost and improve efficiency

3、Closed-loop control algorithm, which ensures high synchronization of four motors of a spindle ingot and consistency of yarn count and twist among spindles

4、Automatic online fault diagnosis, which provides alarm prompt and allows convenient maintenance

5、Single spindle single control. The process parameters of each spindle can be adjusted without interference, which is convenient for proofing yarn

Product advantages

1、High efficiency and energy saving: The direct drive of DC motor takes the place of belt drive, which is more energy-saving

2、Quality improvement: The direct drive control is adopted with small motor spindle speed difference, good twist and even yarn count

3、Variety of patterns: The speed among motors is adjusted through electronic gear ratio, and various yarn such as big-belly yarn and slubby yarn can be produced

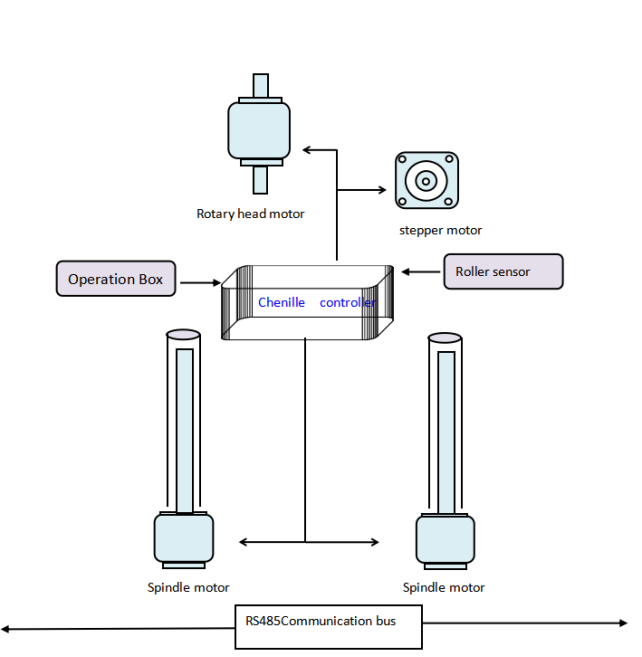

Control Diagram

Related Products

undefined

Leave a message